BACKGROUND

Despite the moves towards automation and digital transformation in view of Industry 4.0, factory workers are still exposed to an unsafe work environment characterized by frequent accidents and low productivity. To improve workplace safety and operational efficiency, Smart Factory Soltuion provides data and statistical analysis through a digital twin, and incident management and prevention features which are enabled by the real-time monitoring of workers and environment.

-

Management of workers

-

Prevention of

accidents -

Improvement of operational efficiency

-

Inventory

management

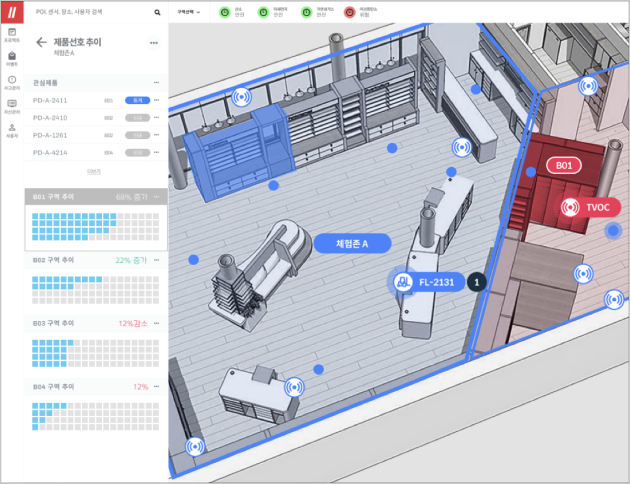

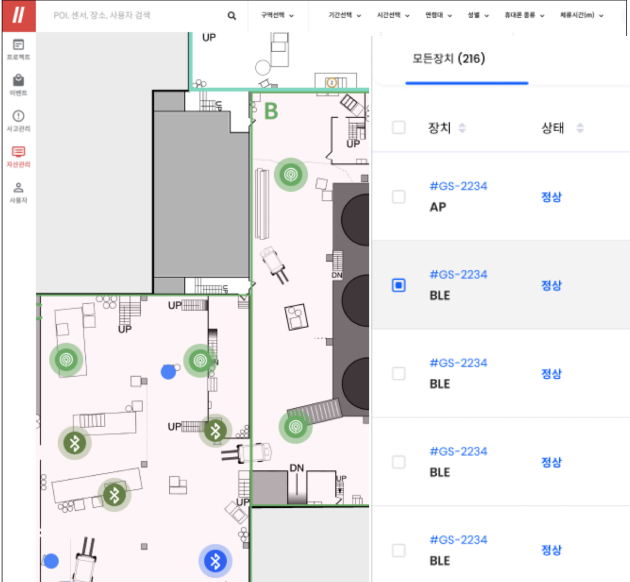

Digital Twin Production lines at factory are created on a virtual dashboard to mirror the actual environment employing high-precision map and space data. Data-based predictions are made possible through real-time data collection, analysis, sharing, visualization and simulation by syncing the virtual dashboard with a data dashboard.

Location of workers/

Monitoring incidents

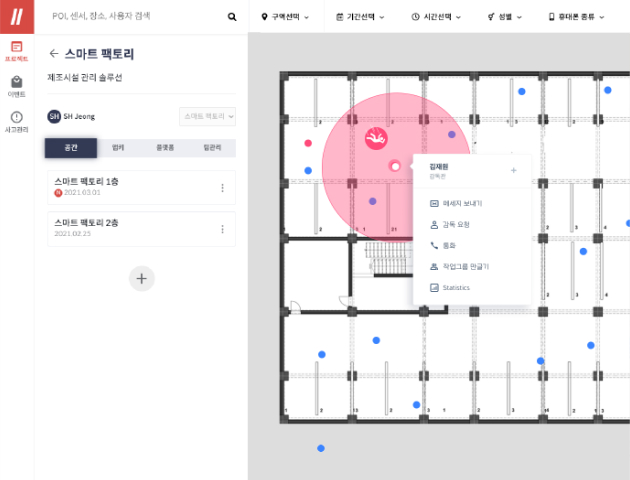

Real-time location of workers in the entire floor and by space as well as past movement data can be checked with filtering options. Also, the sending-message feature enables manager to take relevant actions to respond to incidents, if any.

Management of accidents through work environment monitoring Accidents including fire, explosion and gas leak can be detected through real-time monitoring with environment sensors. An accident spot can be immediately identified with the sensor location and emergency messages can be sent to all workers present at factory.

- Temperature and humidity sensor

- accelerometer

- TVOC sensor

- nitrogen dioxide sensor

- ammonia sensor

- fine dust sensor

Management of accidents through worker monitoring Real-time location of workers in the entire floor and by space as well as past movement data can be checked with filtering options. Also, the sending-message feature enables manager to take relevant actions to respond to incidents, if any.

Logistics / Inventory management system Inventory can be managed easily by printing a barcode or QR code on goods through the Platform. By scanning the code with a smartphone, an inventory list and detailed information can be checked. Processes such as receiving and dispatching goods can be managed on the smartphone application, enabling a real-time inventory management